За Valnit

This system is most often used for administrative and office buildings. The main advantages of rivets are:

– quick and easy installation.

– it is possible to remove the cladding plates for any reason (installation of video surveillance, air conditioning, facade lighting) simply to drill the rivets, to dismantle the boards and then to re-install with new rivets.

– Vibration resistant system, ensuring long life of your facades.

– free thermal expansion and contraction of the plates (panels).

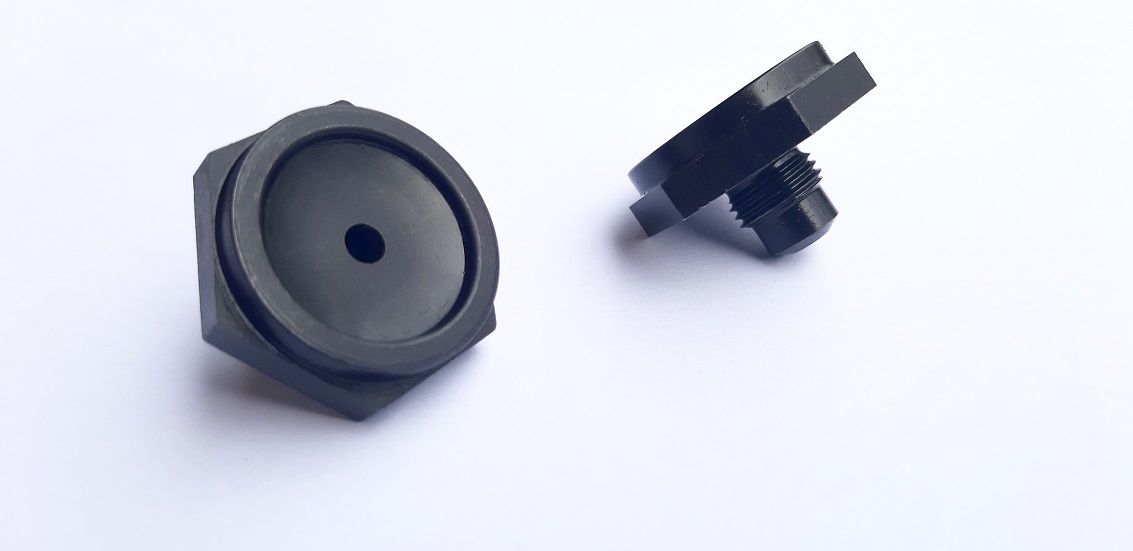

Specially designed blind rivets are used in this system. To ensure long and trouble-free use, the mandrel and rivet body are made of materials with high corrosion resistance.

The rivets have the best looking shape, with a very thin head (less than 1.6 mm).

A two-component, scratch-resistant coating is applied in each RAL color to match the cladding panels.

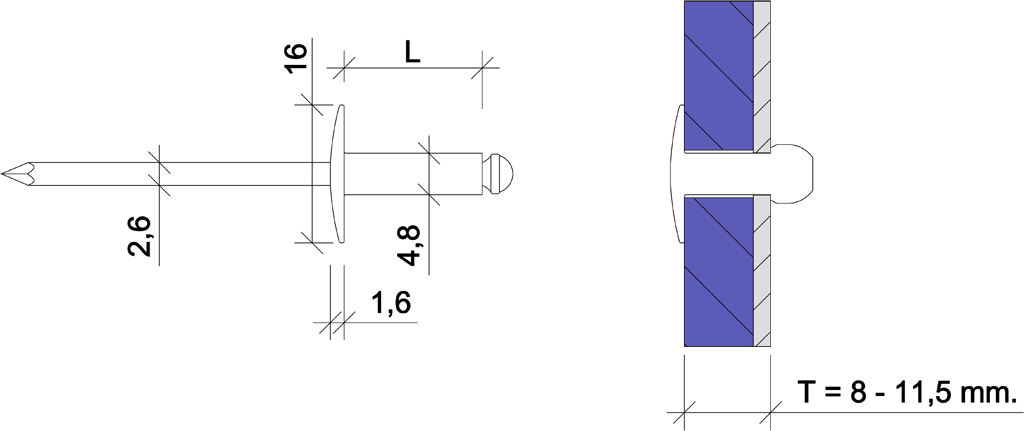

Rivet specifications:

The standard length L = 16 mm. (other lengths are possible on request).

Rivet strength:

Shear strength: 2107 N ± 10%.

Tensile strength: 2842 N ± 10%.

Materials:

Housing: Aluminum AlMg3,5

Donnik: stainless steel A2

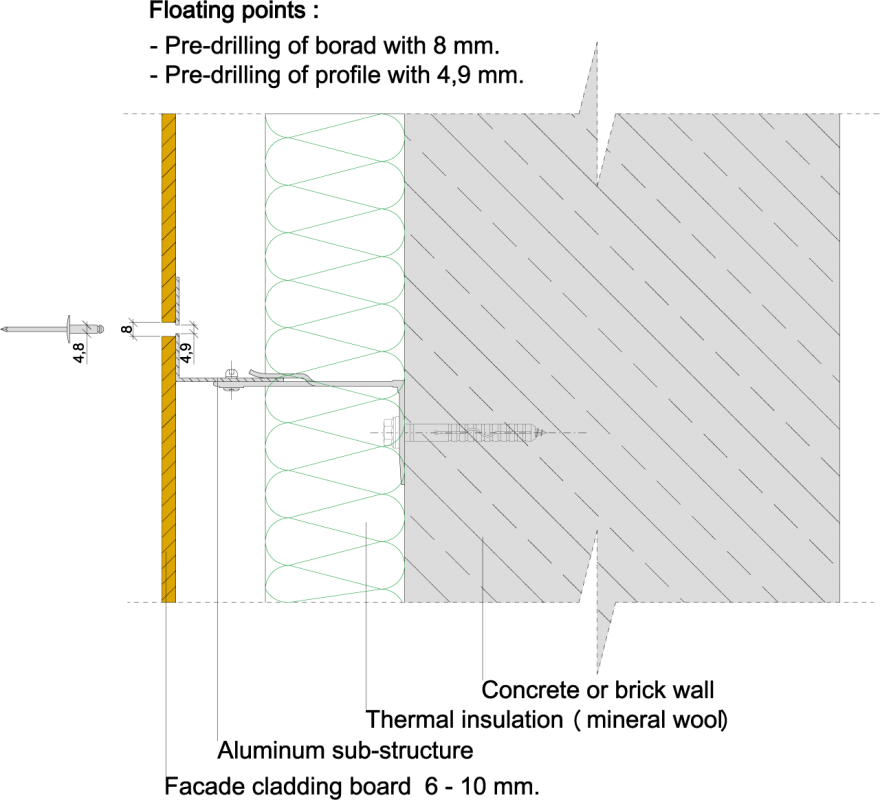

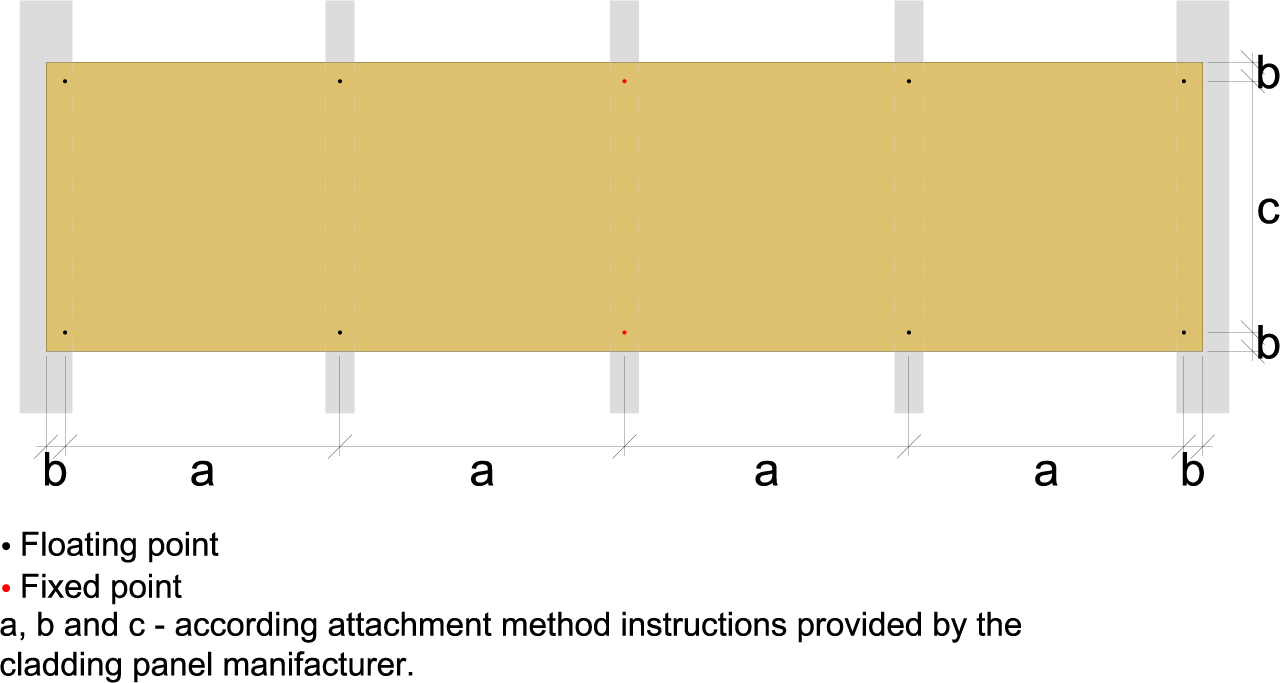

To ensure free thermal expansion and contraction of the slabs, there is a typical drilling method.

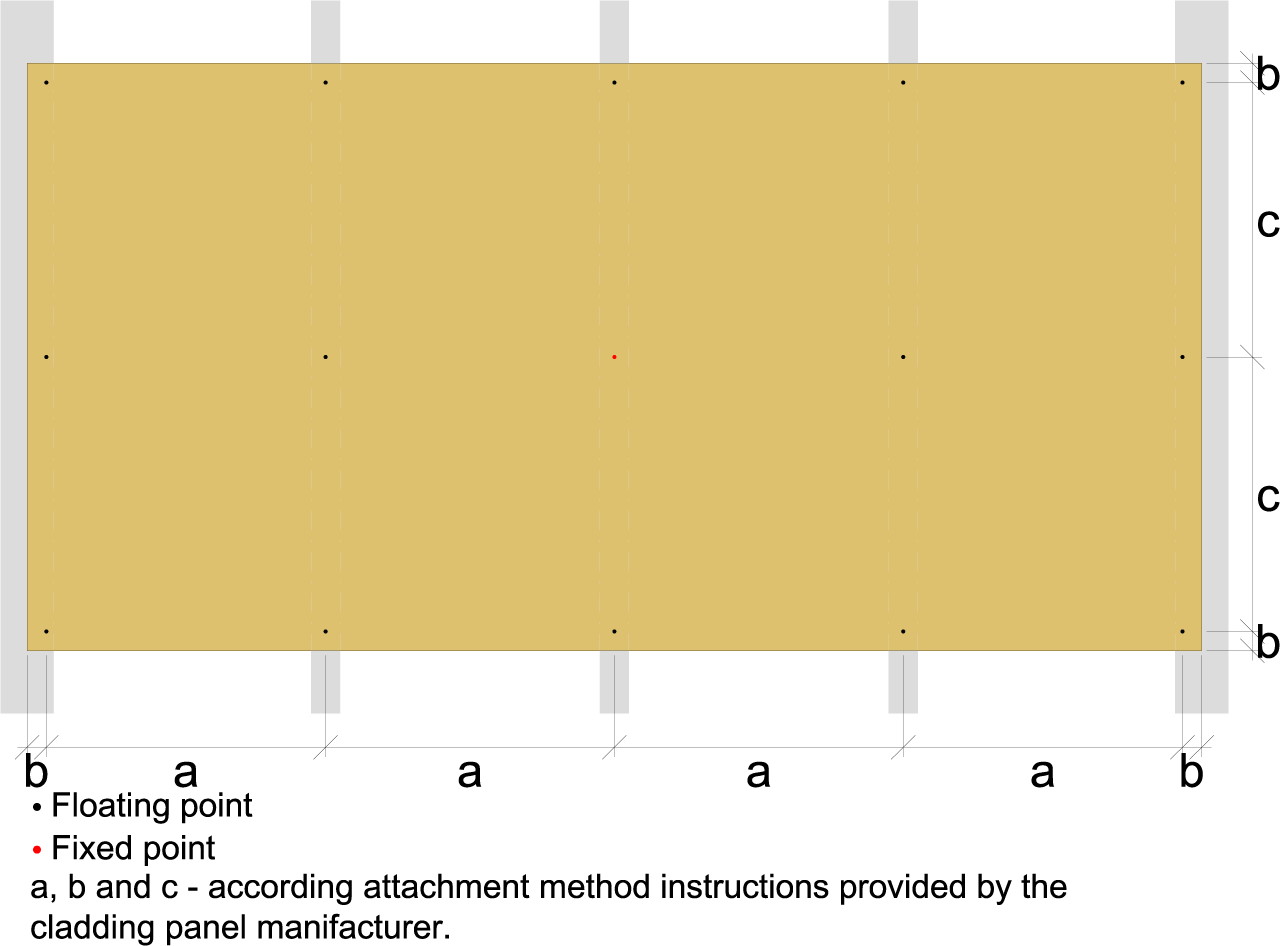

Each hole for the holding rivets of the open fixing board must be 3 mm larger than the diameter of the rivet used, except for the hole in the geometric center of the board, which must be the same size as the rivets. This hole is called a fixed point, and the other (larger) holes are called floating or free fixing points.

4.9 mm. pilot hole required in the composite panel for a fixed point. All other holes depend on the material. Check the fastening method instructions provided by the cladding panel manufacturer.

Additional accessories:

Special nozzle for standard riveting tools.